From poka-yoking common production mistakes to force multiplying the supply chain management (SCM) team, the right IT tools can help improve quality, shorten cycle time and reduce workload. At SigmaTron International, systems strategy is a mix of industry-standard and proprietary systems. While a centralized IT structure oversees deployment of new tools across the organization, IT support activities at each facility often develop and test IT tools relevant to their operational needs. If a tool appears to have relevance across multiple facilities, the corporate IT organization standardizes it to align with a multi-facility deployment, develops required training and deploys it in a phased approach. This approach of exploiting individual facility “working smarter” tools drives innovation faster than a centralized approach alone. At the same time, the corporate IT organization ensures these innovations are robustly tested and able to integrate seamlessly into existing systems prior to company-wide adoption.

This working smarter approach to IT tool integration is paying dividends in the current environment of increased workload and decreased labor availability. The improvements are concentrated in three areas:

- Supply chain management (SCM)

- Production efficiency

- Quality.

Read the full article.

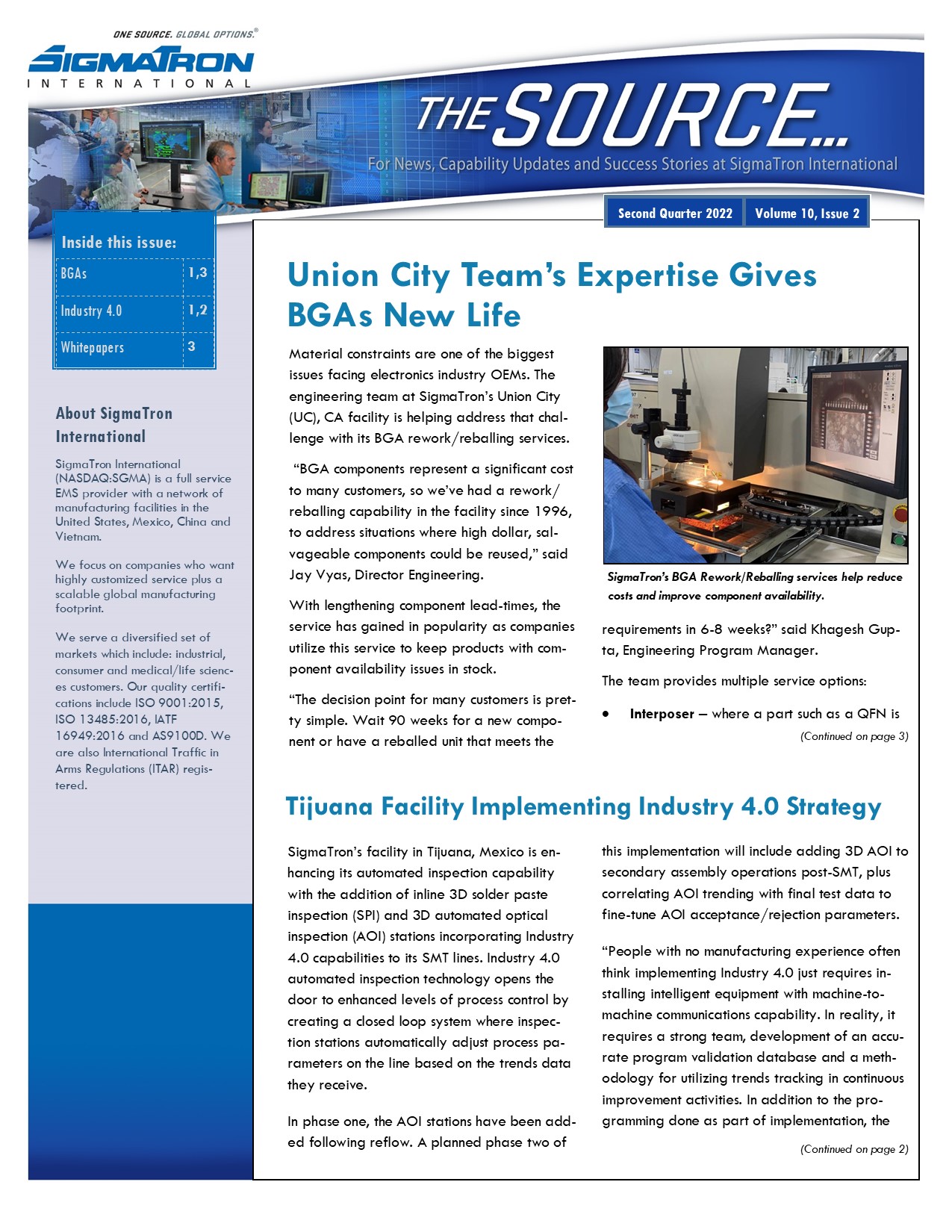

This quarter’s issue of the SigmaTron Source looks at the Union City, CA team’s BGA rework/reballing services and Industry 4.0 enhancements to the Tijuana, Mexico facility’s production lines. Links to SigmaTron’s latest whitepapers are also provided. Read the full issue

This quarter’s issue of the SigmaTron Source looks at the Union City, CA team’s BGA rework/reballing services and Industry 4.0 enhancements to the Tijuana, Mexico facility’s production lines. Links to SigmaTron’s latest whitepapers are also provided. Read the full issue